Recrystallization Recovery: Expert Fixes Revealed!

Recrystallization, a cornerstone technique in organic chemistry, often relies on the judicious selection of a solvent system, which directly impacts the final crystal purity. Solubility differences are a key parameter, as identified by many researchers at the ACS, playing a significant role in the separation process of both the desired compound and its impurities. The pursuit of optimized yields invariably leads to the fundamental question: how to improve percent recovery in recrystallization? Effective control over parameters like temperature gradients and cooling rates will maximize recovery and purity.

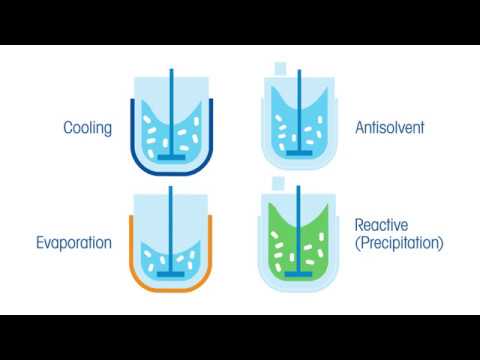

Image taken from the YouTube channel J Michelle Leslie , from the video titled Recrystallization and percent recovery .

Mastering Recrystallization: Maximizing Recovery for Peak Purity

Recrystallization stands as a cornerstone technique in chemical purification, a method relied upon by researchers and manufacturers alike to obtain compounds of exceptional purity.

At its core, recrystallization leverages the principle of differential solubility. A compound is dissolved in a suitable solvent at an elevated temperature, and then, as the solution cools, the compound's solubility decreases, leading to the formation of crystals.

These crystals ideally consist of the purified compound, while impurities remain dissolved in the solvent.

The success of any recrystallization hinges not only on achieving high purity but also on maximizing the percent recovery of the desired compound. A high percent recovery translates to minimal loss of valuable material during the purification process, directly impacting the efficiency and cost-effectiveness of experiments.

The Importance of Percent Recovery

Imagine synthesizing a complex molecule after weeks of painstaking effort, only to lose a significant portion of it during purification. This is where optimizing your recrystallization process becomes crucial.

A high percent recovery ensures that you retain a substantial amount of your product, allowing for further analysis, experimentation, or downstream applications.

Furthermore, a poor recovery can skew experimental results, making accurate data interpretation challenging. In industrial settings, maximizing recovery directly translates to increased profitability and reduced waste.

Recrystallization: A Brief Overview

The process involves dissolving an impure solid in a hot solvent, creating a saturated solution. As the solution cools, the purified compound crystallizes out, leaving impurities behind in the solution.

These crystals are then separated from the solvent via filtration and dried, yielding the purified product. The key lies in selecting a solvent in which the desired compound is highly soluble at high temperatures but poorly soluble at low temperatures, while the impurities exhibit the opposite behavior.

Achieving Optimal Results: Our Objective

This editorial will serve as a comprehensive guide to optimizing percent recovery in recrystallization. We aim to equip you with expert-backed solutions and practical strategies to overcome common challenges and achieve exceptional purification results.

We will delve into the critical factors that influence percent recovery, including solvent selection, cooling rate, crystal formation techniques, filtration methods, and drying strategies.

By understanding these principles and implementing the recommended techniques, you can significantly improve your recrystallization outcomes, ensuring minimal product loss and maximizing the value of your efforts.

Thesis: Unlocking the Secrets to High Recovery

This blog explores the critical factors influencing percent recovery in recrystallization and offers practical strategies for improvement. From solvent selection to drying techniques, we will dissect each step of the process, providing actionable insights to elevate your purification game and achieve optimal results.

Mastering the art of recrystallization is about more than just obtaining pure crystals; it's about doing so efficiently. Understanding the factors that influence how much of your desired compound you actually recover is essential.

Understanding Percent Recovery: The Foundation of Success

Percent recovery is the metric by which we measure the efficiency of a recrystallization. It quantifies how much of the desired compound is retained after the purification process. Understanding and maximizing percent recovery is, therefore, not merely a procedural step but a fundamental principle of effective chemical purification.

Defining Percent Recovery

Percent recovery is the ratio of the mass of the pure crystals obtained after recrystallization to the mass of the impure compound used at the start, expressed as a percentage.

The formula is straightforward:

Percent Recovery = (Mass of Pure Crystals / Mass of Impure Compound)

**100%

For example, if you start with 10 grams of an impure compound and obtain 8 grams of pure crystals after recrystallization, your percent recovery is (8g / 10g)** 100% = 80%.

Significance as a Measure of Efficiency

Percent recovery is a critical indicator of how efficiently a recrystallization has been performed.

A high percent recovery signifies minimal loss of the desired compound during the process. This leads to less waste and better resource utilization.

Conversely, a low percent recovery suggests significant losses, potentially due to suboptimal solvent choice, poor technique, or inherent properties of the compound.

Optimizing percent recovery is therefore crucial for minimizing waste, maximizing yield, and ensuring the cost-effectiveness of any recrystallization.

Factors Affecting Percent Recovery

Several factors can influence percent recovery, some controllable and others inherent to the compound or the process itself.

Solubility

Solubility is arguably the most important factor. The ideal solvent should dissolve the compound well at high temperatures and poorly at low temperatures.

If the compound is too soluble in the chosen solvent even at cold temperatures, a significant portion will remain dissolved during cooling, resulting in lower recovery.

Product Loss During Filtration and Transfer

Each transfer step introduces the possibility of loss. Crystals can adhere to glassware, filter paper, or spatulas.

Careful and quantitative transfer techniques are crucial to minimize these losses. Pre-wetting the filter paper with the solvent can help to reduce crystal adhesion.

Incomplete Drying

If the crystals are not completely dry before weighing, the residual solvent will contribute to an artificially inflated mass, leading to an overestimation of the recovery.

However, vigorous drying might lead to decomposition of the crystals, resulting in the loss of material and an underestimation of recovery. The drying process needs to be optimized.

Other Potential Losses

Other factors include losses due to side reactions, decomposition of the compound during the process, or the formation of unwanted byproducts.

The Critical Role of Solubility

Solubility plays a pivotal role in determining the success of a recrystallization, directly impacting the percent recovery.

The ideal solvent exhibits a significant difference in the compound's solubility between high and low temperatures.

This large solubility difference allows for a large portion of the compound to crystallize out upon cooling.

If the solubility difference is small, only a small amount of the compound will crystallize.

Careful consideration of solubility is, therefore, essential for maximizing the yield and achieving a high percent recovery in recrystallization.

Percent recovery serves as a powerful tool to evaluate the success of a recrystallization. However, achieving high percent recovery isn't simply about calculation; it is also deeply tied to the practical execution of the process. One of the most influential and initial decisions that profoundly shapes the outcome of your recrystallization process is selecting the right solvent.

Solvent Selection: The Cornerstone of Effective Recrystallization

Choosing the right solvent is paramount to successful recrystallization. It can be seen as the cornerstone upon which the entire process rests. A poorly chosen solvent can lead to low yields, impure products, or even complete failure of the recrystallization. The solvent dictates the solubility of both the desired compound and the impurities at different temperatures.

Therefore, a careful and informed solvent selection is not merely a preliminary step; it's a strategic decision that directly impacts the efficiency and effectiveness of the purification process.

The "Like Dissolves Like" Principle

The guiding principle behind solvent selection is the adage "like dissolves like." This principle states that polar solvents tend to dissolve polar solutes, while nonpolar solvents dissolve nonpolar solutes. This is due to the intermolecular forces between the solvent and solute molecules. For effective recrystallization, we need to exploit this principle to our advantage.

Polar solvents, such as water, alcohols (e.g., methanol, ethanol), and acetic acid, possess significant dipole moments due to uneven electron distribution in their molecular structure.

These solvents effectively dissolve polar compounds like sugars, salts, and carboxylic acids.

On the other hand, nonpolar solvents, such as hexane, diethyl ether, and toluene, have relatively even electron distribution and lack significant dipole moments.

These are better suited for dissolving nonpolar compounds like hydrocarbons, lipids, and aromatic compounds.

For instance, consider trying to dissolve table salt (NaCl), a highly polar ionic compound, in hexane, a nonpolar solvent. You'd find it practically insoluble. Conversely, dissolving oil (composed of nonpolar hydrocarbons) in water is equally ineffective.

Choosing a Solvent Based on Compound Properties and Impurities

Selecting the ideal solvent involves considering the properties of both the target compound and the impurities you want to remove. The best solvent will dissolve the desired compound well at high temperatures and poorly at low temperatures. This creates a significant difference in solubility, allowing the compound to crystallize out upon cooling.

Ideally, the impurities should be either highly soluble in the chosen solvent at all temperatures or practically insoluble, allowing for easy separation via filtration. If the impurities have similar solubility properties to the target compound, separation becomes much more challenging.

Here's a practical approach to solvent selection:

- Determine the Polarity of Your Compound: Consider its functional groups (e.g., hydroxyl, carboxyl, amine, etc.).

- Research Solvent Properties: Consult solvent property tables to understand their polarity, boiling point, and safety characteristics.

- Conduct Solubility Tests: Perform small-scale solubility tests with different solvents at both high and low temperatures to observe the dissolution behavior of your compound.

- Consider Mixed Solvents: Sometimes, a single solvent isn't ideal. A mixture of two miscible solvents can provide the right balance of solubility for your compound and impurities.

The Importance of Solvent Polarity

Solvent polarity is a critical factor influencing solubility. A solvent's polarity is measured by its dielectric constant (ε), which reflects its ability to reduce the electrostatic attraction between oppositely charged ions. Solvents with high dielectric constants (e.g., water, ε ≈ 80) are highly polar, while those with low dielectric constants (e.g., hexane, ε ≈ 2) are nonpolar.

The key is to match the polarity of the solvent to that of the compound you wish to dissolve. However, recrystallization often involves finding a solvent where the temperature dependence of solubility is optimal.

This sometimes means choosing a solvent that isn't a "perfect" match in terms of polarity but offers the greatest change in solubility with temperature.

Common Solvents and Their Polarities

The following table provides a reference for common solvents used in recrystallization and their relative polarities. This is a starting point, but remember to consider other factors like boiling point, safety, and cost when making your selection.

| Solvent | Polarity | Boiling Point (°C) | Considerations |

|---|---|---|---|

| Water | Very Polar | 100 | High polarity, inexpensive, non-toxic. May not be suitable for hydrophobic compounds. |

| Methanol | Polar | 65 | Good general-purpose polar solvent. Can dissolve a wide range of compounds. |

| Ethanol | Polar | 78 | Similar to methanol, but less toxic. |

| Acetone | Polar Aprotic | 56 | Good for dissolving moderately polar compounds. High volatility. |

| Ethyl Acetate | Moderately Polar | 77 | Versatile solvent with moderate polarity. Often used in mixtures. |

| Dichloromethane | Moderately Polar | 40 | Good for dissolving a range of organic compounds. Use with caution (toxicity). |

| Diethyl Ether | Nonpolar | 35 | Highly volatile and flammable. Good for nonpolar compounds. |

| Hexane | Nonpolar | 69 | Excellent for dissolving nonpolar compounds. Relatively inexpensive. |

| Toluene | Nonpolar | 111 | Aromatic solvent, good for dissolving aromatic compounds. Use with caution (toxicity). |

Solvent selection lays the foundation for recrystallization, but the rate at which you cool your solution is equally critical in determining the size and purity of the crystals you obtain. Cooling rate profoundly influences the kinetics of crystal formation, affecting both crystal size and the inclusion of impurities.

Controlling the Cooling Rate: Crystal Size and Purity Optimization

The dance between crystal size and purity is often dictated by a single, seemingly simple factor: the cooling rate. The speed at which a saturated solution is cooled dramatically influences the crystal formation process.

It impacts everything from the size of the resulting crystals to their overall purity. Understanding and mastering this aspect of recrystallization is vital for optimizing your results.

The Influence of Cooling Rate on Crystal Morphology

The cooling rate significantly influences the morphology of the crystals that form. A slow, controlled cooling process generally favors the formation of larger, more well-defined crystals. This is because molecules have sufficient time to find their optimal positions within the crystal lattice.

Conversely, rapid cooling often leads to the formation of smaller, less uniform crystals. This happens because the molecules are forced to aggregate quickly, without the time to arrange themselves perfectly.

Slow Cooling: Fostering Purity Through Order

Slow cooling is often the preferred method when purity is the primary concern. As the solution cools gradually, molecules of the desired compound slowly precipitate out of the solution and arrange themselves into an organized crystalline structure.

The gradual process allows impurities to remain in solution. It prevent them from being incorporated into the growing crystal lattice.

The slow pace provides an opportunity for dynamic equilibrium to be established between the solid and liquid phases. This favors the inclusion of only the desired molecules into the crystal.

Rapid Cooling: Speed vs. Selectivity

While speed might seem appealing, rapid cooling often compromises purity. When a solution is cooled too quickly, the supersaturation level rises rapidly.

This leads to a burst of nucleation events. Numerous tiny crystals form almost simultaneously.

These crystals grow quickly, but the rapid growth can trap impurities within the crystal lattice. The result is a larger quantity of crystals, but with a lower overall purity.

In essence, rapid cooling sacrifices selectivity for speed, resulting in crystals contaminated with unwanted byproducts.

Impurity Incorporation: A Consequence of Hasty Cooling

The most significant drawback of rapid cooling is the increased likelihood of impurity incorporation. As crystals form quickly, they don't discriminate as effectively between the desired compound and impurities.

Impurities that would otherwise remain in solution during slow cooling become trapped within the growing crystal lattice, resulting in a less pure product.

This is especially problematic when the impurities have a similar structure or size to the target compound, as they can more easily fit into the crystal structure.

Fine-Tuning the Cooling Rate for Optimal Results

The ideal cooling rate is not a one-size-fits-all parameter. It depends on the specific compound being recrystallized, the solvent used, and the nature of the impurities present. Experimentation is often required to find the sweet spot.

Start with a slow cooling rate and observe the crystal formation process. If the crystals are too small or the yield is too low, you can gradually increase the cooling rate. However, be mindful of the potential for decreased purity.

Techniques like using a cooling bath or wrapping the flask in an insulating material can help to control the cooling rate more precisely. Monitoring the temperature of the solution throughout the cooling process can also provide valuable insights.

Controlling the cooling rate is just one piece of the recrystallization puzzle. While it sets the stage for crystal formation, the processes of nucleation and crystal growth themselves are the actors that ultimately determine the outcome. Understanding these processes and how to manipulate them is crucial for achieving optimal yield and purity.

Crystal Formation: Nucleation, Growth, and Optimization Techniques

The formation of crystals from a solution is a two-step process: nucleation and crystal growth. Each plays a distinct role, and understanding the nuances of each is key to mastering recrystallization.

Nucleation: The Birth of a Crystal

Nucleation is the initial stage where a few ions, atoms, or molecules become arranged in a pattern characteristic of a crystalline solid, forming a stable nucleus. Think of it as the seed from which a crystal will grow.

There are two primary types of nucleation:

-

Primary Nucleation: This occurs spontaneously in a solution that is free from any pre-existing crystalline material. It requires a high degree of supersaturation.

-

Secondary Nucleation: This is induced by the presence of existing crystals or other surfaces within the solution. It can occur at lower levels of supersaturation than primary nucleation.

The rate of nucleation is highly sensitive to factors like temperature, supersaturation, and the presence of impurities.

Crystal Growth: Building the Structure

Once a stable nucleus has formed, crystal growth begins. This is the process where additional molecules, ions, or atoms from the solution deposit onto the existing crystal surface, expanding its size and solidifying its structure.

Crystal growth is influenced by several factors, including:

-

Supersaturation: A higher degree of supersaturation generally leads to faster crystal growth.

-

Temperature: Temperature affects the rate at which molecules can move and attach to the crystal surface.

-

Impurities: The presence of impurities can hinder crystal growth by blocking active sites on the crystal surface.

The goal is to promote slow, controlled crystal growth. This allows the molecules to arrange themselves in a highly ordered manner, leading to larger, purer crystals.

Seeding: Taking Control of Nucleation

One of the most effective ways to control crystal formation is through seeding. Seeding involves adding a small amount of pure crystalline material of the target compound to the supersaturated solution.

This provides a pre-existing surface for secondary nucleation, encouraging crystal growth to occur around the seed crystals.

Benefits of Seeding:

-

Promotes Nucleation: Seeding helps to overcome the energy barrier to primary nucleation, especially when spontaneous nucleation is slow or difficult to achieve.

-

Controls Crystal Size: By introducing a controlled number of seed crystals, you can influence the final size distribution of the crystals. Fewer seed crystals lead to larger crystals, while more seed crystals lead to smaller crystals.

-

Enhances Purity: Seeding encourages the desired compound to crystallize preferentially, potentially excluding impurities from the crystal lattice.

How to Seed Effectively:

-

Prepare a Saturated Solution: Ensure your solution is saturated with the compound you wish to crystallize.

-

Cool the Solution: Cool the solution to a temperature where it is slightly supersaturated.

-

Add Seed Crystals: Introduce a small amount of finely ground, pure crystals of the compound.

-

Observe and Monitor: Observe the solution for crystal growth. If no crystals form, you may need to cool the solution further or add more seed crystals.

Strategies for Optimized Crystal Quality and Yield

Beyond seeding, several other strategies can be employed to control nucleation and crystal growth, leading to improved crystal quality and yield:

-

Controlled Cooling: Maintain a slow, consistent cooling rate to encourage uniform crystal growth and minimize the incorporation of impurities.

-

Stirring: Gentle stirring helps to distribute the solute evenly throughout the solution and promotes contact between the solute molecules and the growing crystal surfaces. Avoid vigorous stirring, as this can lead to the formation of smaller, less uniform crystals.

-

Solvent Choice: Select a solvent that provides the optimal level of solubility for your compound at different temperatures. A solvent with a large difference in solubility between hot and cold temperatures is ideal for recrystallization.

-

Avoiding Supersaturation Extremes: While supersaturation is necessary for nucleation and crystal growth, excessive supersaturation can lead to rapid, uncontrolled crystallization, resulting in smaller, less pure crystals.

By carefully controlling the conditions of nucleation and crystal growth, you can significantly improve the yield and purity of your recrystallized product. These techniques, combined with proper solvent selection and cooling rate control, form the foundation of successful recrystallization.

Controlling the cooling rate is just one piece of the recrystallization puzzle. While it sets the stage for crystal formation, the processes of nucleation and crystal growth themselves are the actors that ultimately determine the outcome. Understanding these processes and how to manipulate them is crucial for achieving optimal yield and purity.

Filtration Techniques: Minimizing Product Loss and Removing Impurities

Filtration stands as a critical step in recrystallization, acting as the gatekeeper to purity. It’s the process by which insoluble impurities are removed, ensuring that only the desired compound proceeds further. However, a poorly executed filtration can lead to significant product loss, undermining the entire recrystallization effort. The key is to employ techniques that maximize impurity removal while simultaneously minimizing the sacrifice of our precious product.

The Role of Hot Filtration

Sometimes, impurities stubbornly refuse to dissolve, even at the boiling point of the solvent. In these cases, hot filtration becomes essential. This technique involves filtering the solution while it's still hot, keeping the desired compound dissolved and allowing the insoluble impurities to be trapped by the filter.

The most common technique involves gravity filtration using fluted filter paper.

Ensuring Success with Hot Filtration

The success of hot filtration hinges on maintaining the solution's temperature throughout the process. Cooling can cause premature crystallization, clogging the filter and leading to substantial product loss.

To prevent this, consider the following:

- Preheat all glassware: Use a hot plate or oven to warm the funnel and receiving flask.

- Use a short-stemmed funnel: This minimizes surface area for cooling.

- Keep the solution at or near its boiling point: Work quickly to prevent crystallization.

Minimizing Product Loss During Filtration

Even without insoluble impurities, filtration can still lead to product loss if not performed carefully. Adsorption to the filter paper, incomplete transfer, and spillage can all contribute to a lower percent recovery.

Strategies for Loss Reduction

Here are several proven techniques to minimize product loss during filtration:

- Pre-wet the filter paper: Saturate the filter paper with a small amount of fresh, hot solvent before filtering the main solution. This minimizes adsorption of the desired compound to the paper.

- Quantitative Transfer: Use multiple small washes of hot solvent to rinse the original flask and ensure all crystals are transferred to the filter. Use a glass stirring rod with a rubber policeman.

- Use the Correct Filter Paper Size: Select a filter paper size that is appropriate for the volume of the solution. An oversized filter paper can absorb an unnecessary amount of the solution.

- Careful Handling: Avoid spills and splashes by using appropriate techniques and pouring slowly.

Optimizing Filtration Speed

Slow filtration can prolong the process, increasing the risk of cooling and crystallization within the filter. Fluted filter paper offers a simple yet effective solution. The fluted design increases the surface area available for filtration, thereby accelerating the process. Folding the filter paper in a fluted manner creates channels that allow air to escape, increasing the speed of the filtration.

By mastering these filtration techniques, we can significantly reduce product loss and achieve optimal purity in our recrystallization efforts.

Drying Strategies: Ensuring Complete Solvent Removal and Maximizing Yield

The pursuit of pure crystals doesn't end with filtration. Proper drying is the final, crucial step in recrystallization, ensuring accurate yield measurements and preventing decomposition. Incomplete solvent removal inflates the apparent mass, leading to inaccurate yield calculations and skewed experimental results. Furthermore, residual solvent can, in some cases, promote unwanted side reactions or degrade the stability of the purified compound over time.

Therefore, selecting an appropriate drying method that efficiently removes all traces of the solvent without compromising the integrity of the crystals is essential for maximizing the recovery of pure compounds.

Methods for Drying Recrystallized Crystals

Various drying techniques exist, each with its own set of advantages and disadvantages. The choice of method depends on factors such as the nature of the compound, the solvent used, and the available equipment.

Air Drying

Air drying is perhaps the simplest method, involving spreading the crystals on a filter paper or watch glass and allowing the solvent to evaporate at room temperature.

This method is suitable for compounds that are stable in air and have relatively low boiling point solvents.

However, it is slow and may not be effective for removing high-boiling solvents completely. Furthermore, air drying can lead to contamination from airborne particles.

Vacuum Drying

Vacuum drying involves placing the crystals in a vacuum desiccator or oven and reducing the pressure.

This lowers the boiling point of the solvent, accelerating its evaporation. Vacuum drying is more efficient than air drying and is suitable for a wider range of compounds and solvents.

However, it requires specialized equipment and may not be suitable for compounds that are volatile or sensitive to pressure.

Drying Oven

A drying oven provides a controlled elevated temperature to accelerate solvent evaporation.

It's a common method, but careful temperature control is essential.

Excessive heat can decompose the product.

Oven drying is suitable for thermally stable compounds but should be avoided for heat-sensitive substances.

Other Drying Techniques

Other specialized techniques include the use of a lyophilizer (freeze dryer), which is particularly useful for heat-sensitive compounds.

These methods involve freezing the solution and then subliming the solvent under vacuum.

Preventing Decomposition During Drying

The most critical aspect of drying is preventing the decomposition of the desired product.

Some compounds are sensitive to heat, air, light, or moisture, and prolonged exposure to these conditions can lead to degradation.

Therefore, it's crucial to choose a drying method that minimizes exposure to these factors.

Here's how:

- Use the mildest drying conditions possible. If air drying is sufficient, avoid using a drying oven.

- Protect light-sensitive compounds from light by drying them in the dark or using amber-colored glassware.

- Use a desiccator to remove moisture from the drying environment.

- Monitor the crystals closely during drying and stop the process as soon as they are dry.

Ensuring Complete Solvent Removal

The ultimate goal of drying is to remove all traces of solvent. However, it can be challenging to determine when the crystals are completely dry.

Here are several ways to test this:

- Constant Weight: Weigh the crystals periodically during drying. When the weight remains constant over successive measurements, it indicates that all the solvent has been removed.

- Spectroscopic Analysis: Techniques like NMR or IR spectroscopy can detect residual solvent in the crystal lattice.

- Visual Inspection: While not always reliable, observing the crystals for any signs of wetness or clumping can provide an initial indication of solvent presence.

Achieving complete solvent removal is essential for accurate yield determination and for ensuring the stability and purity of the final product. A meticulous approach to drying, combined with careful monitoring, will ensure the success of your recrystallization efforts.

Troubleshooting: Common Challenges and Expert Solutions

Even with meticulous planning and execution, recrystallization can present unexpected hurdles. Addressing these challenges effectively is key to salvaging a potentially compromised experiment and achieving optimal percent recovery. Let's delve into some common pitfalls and explore expert-backed solutions.

Addressing Solubility Issues

One of the most frustrating challenges in recrystallization is encountering a compound with low solubility in the chosen solvent, even at elevated temperatures. This can significantly limit the amount of material that can be purified in a single batch, leading to a lower overall yield.

Exploring Mixed Solvents

When a single solvent proves inadequate, a mixed solvent system can often provide the necessary solubility characteristics. The key is to select two miscible solvents: one in which the compound is highly soluble and another in which it is poorly soluble.

The solvent in which the compound is highly soluble is used to dissolve the compound initially, and then the second solvent is added slowly until the solution becomes saturated or slightly cloudy. Heating may be required to maintain solubility during this process.

The ideal ratio of solvents needs to be determined experimentally, as it depends on the specific compound and solvents being used. A good starting point is to try a 1:1 mixture and adjust the ratio based on the observed solubility.

Alternative Solvent Selection

If mixed solvents don't provide the desired solubility, revisiting the initial solvent selection is warranted. Consider solvents with different polarities or functional groups that might interact more favorably with the compound. Consult solubility tables and literature data to guide your choice.

Minimizing Product Loss During Filtration

Filtration is a critical step in removing insoluble impurities, but it can also be a source of significant product loss if not performed carefully. Small losses during filtration can quickly add up, leading to a disappointing overall yield.

Quantitative Transfers

To minimize product loss during transfer, perform quantitative transfers. This involves rinsing the original container multiple times with small portions of the hot recrystallization solvent, ensuring that all the remaining solid is dissolved and transferred to the filtration apparatus.

Use a glass stir rod and a rubber policeman to dislodge any crystals clinging to the sides of the container. Combine all rinsings and filter them through the same filter paper.

Optimizing Filter Paper Size

Using a filter paper that is unnecessarily large can lead to significant solvent absorption and subsequent product loss. Choose a filter paper size that is only slightly larger than the funnel, minimizing the surface area available for solvent retention.

Consider using a pre-weighed filter paper. After filtration and drying, the difference in weight will provide a more accurate measure of the recovered crystals.

Optimizing Cooling Rate

The rate at which a solution cools during recrystallization has a profound impact on crystal size, purity, and ultimately, yield.

Avoiding Oiling Out

A common problem, especially with low-melting solids, is oiling out, where the compound separates from solution as an oil rather than forming crystals. This occurs when the compound's melting point is lower than the solution's temperature, causing it to solidify as an amorphous mass, trapping impurities.

To avoid oiling out, cool the solution slowly and gradually. Start by allowing the solution to cool to room temperature, then place it in an ice bath to further reduce the temperature.

Seeding the solution with a small amount of pure crystals can also help initiate crystal formation and prevent oiling out. If oiling out occurs, try redissolving the oil in a minimal amount of hot solvent and then cooling the solution more slowly, ideally with seeding.

Controlled Cooling Strategies

Achieving optimal crystal formation requires controlled cooling. Insulating the flask during cooling can help slow down the cooling rate and promote the formation of larger, purer crystals. Alternatively, using a programmable cooler allows for precise temperature control during the cooling process.

Enhancing Crystal Quality

The quality of the crystals directly affects their purity and ease of handling. Small, needle-like crystals can be difficult to filter and wash, leading to product loss. Large, well-formed crystals are generally easier to work with and tend to be purer.

Promoting Nucleation by Seeding

Seeding is a powerful technique for initiating crystal formation and controlling crystal size. Adding a small amount of pure crystals to a saturated solution provides nucleation sites, encouraging the compound to crystallize out of solution.

The seed crystals should be of the same compound being recrystallized and should be as pure as possible. Gently scratch the inside of the flask with a glass rod to create nucleation sites if seed crystals are not available.

Optimizing Crystal Growth

Once nucleation has occurred, it is important to provide the conditions for optimal crystal growth. This typically involves allowing the solution to cool slowly and undisturbed. Avoid sudden temperature changes or agitation, as these can disrupt crystal formation and lead to smaller, less pure crystals.

Practical Examples: Case Studies in Recrystallization Success

Recrystallization, while grounded in fundamental principles, often demands a nuanced and adaptive approach in practice. To illustrate the application of the strategies discussed, let's examine two case studies. These examples showcase the challenges encountered during recrystallization and the specific solutions employed to significantly improve percent recovery.

Case Study 1: Improving Percent Recovery of Benzoic Acid

Benzoic acid, a common organic compound, is frequently used in introductory chemistry labs to demonstrate recrystallization techniques. A typical challenge is achieving satisfactory recovery due to its moderate solubility in water, the common recrystallization solvent.

The Initial Challenge

Imagine a scenario where a student begins with 5.0 grams of impure benzoic acid and attempts recrystallization from water. Following standard procedures, they obtain only 2.8 grams of purified benzoic acid. This translates to a dismal 56% recovery, far from ideal. Where did the loss occur, and how can it be mitigated?

Identifying the Loss Points

Careful analysis reveals several potential loss points. Firstly, significant benzoic acid remains dissolved in the mother liquor after cooling. Benzoic acid's solubility in water increases dramatically with temperature (poor at cold and high at hot). Thus, the cooling process doesn’t induce full preciptation, and a large portion is carried with the solvent.

Secondly, small losses occur during transfer between beakers and filtration. Even meticulous technique can result in small quantities of material adhering to glassware or being trapped within the filter paper.

Finally, some benzoic acid may be lost if the drying process is not optimized, resulting in an underestimate of the total mass recovered.

Implementing Solutions for Enhanced Recovery

To address these challenges, several modifications can be implemented:

-

Solvent Volume Optimization: Minimize the volume of water used to dissolve the benzoic acid during the initial heating step. Using just enough solvent to dissolve the solid at the boiling point reduces the amount of benzoic acid that remains in the mother liquor upon cooling.

-

Ice Bath Cooling: Instead of allowing the solution to cool slowly at room temperature, place the flask in an ice bath to maximize precipitation. The colder temperature causes more benzoic acid to precipitate out of the solution, improving yield.

-

Seeding: If crystal formation is slow to initiate, adding a seed crystal of pure benzoic acid can help kickstart nucleation, encouraging more of the dissolved compound to solidify.

-

Quantitative Transfer Techniques: Employ techniques for quantitative transfer, such as rinsing the original flask with small portions of ice-cold water and transferring the rinses to the filtration apparatus. This helps to recover any benzoic acid adhering to the glassware.

-

Washing with Cold Solvent: Before drying, wash the collected crystals on the filter paper with a small amount of ice-cold water. This removes any residual impurities adhering to the surface of the crystals without dissolving a significant amount of the desired product due to the solvent's low temperature.

-

Optimized Drying: Dry the crystals thoroughly in a drying oven or under vacuum to ensure complete removal of water. Weigh the crystals only after they are completely dry to obtain an accurate yield measurement.

Results

By implementing these strategies, the student can expect a significant improvement in percent recovery. In a repeat experiment, the student recovered 4.2 grams of purified benzoic acid from the initial 5.0 grams, resulting in an improved recovery of 84%.

This result showcases the power of strategic intervention and thoughtful optimization in maximizing yield.

Case Study 2: Optimizing Solvent Selection for Naphthalene Purification

Naphthalene, a polycyclic aromatic hydrocarbon, is another common compound used to teach recrystallization. However, the challenge here lies in selecting the optimal solvent for purification, as naphthalene exhibits reasonable solubility in a variety of organic solvents.

The Initial Challenge

Suppose a chemist attempts to purify crude naphthalene using ethanol as the recrystallization solvent. While some purification is achieved, the recovery is poor, and the resulting crystals are not as pure as desired.

The issue stems from naphthalene's relatively high solubility in ethanol even at lower temperatures, leading to substantial losses in the mother liquor.

Exploring Alternative Solvents

A more suitable solvent for naphthalene recrystallization is methanol. Naphthalene is less soluble in methanol, especially at lower temperatures. This lower solubility translates to a higher yield of purified crystals and a greater degree of impurity removal.

Implementing Solvent Optimization Strategies

The chemist repeats the recrystallization, this time using methanol as the solvent. The procedure involves:

-

Dissolving the crude naphthalene in a minimal amount of hot methanol.

-

Filtering the hot solution to remove any insoluble impurities.

-

Allowing the solution to cool slowly to room temperature, followed by further cooling in an ice bath.

-

Collecting the purified naphthalene crystals by filtration.

-

Washing the crystals with a small amount of cold methanol.

-

Drying the crystals to constant weight.

Assessing the Results

Using methanol significantly improves the percent recovery of naphthalene compared to using ethanol. The resulting crystals are also noticeably purer, as evidenced by a sharper melting point range.

This example highlights the critical importance of solvent selection in achieving successful recrystallization and maximizing product recovery. A carefully chosen solvent can dramatically improve both the yield and the purity of the final product.

These case studies demonstrate that recrystallization is not simply a rote procedure, but a process that benefits significantly from careful consideration of the compound's properties, strategic optimization of the experimental parameters, and thoughtful troubleshooting. By understanding and addressing the specific challenges associated with each compound, researchers can maximize percent recovery and obtain highly purified materials.

Video: Recrystallization Recovery: Expert Fixes Revealed!

Recrystallization Recovery: Frequently Asked Questions

This FAQ addresses common queries regarding recrystallization recovery and strategies for maximizing your yield.

Why is my percent recovery in recrystallization so low?

Low percent recovery in recrystallization often stems from solubility losses. Some of your desired compound remains dissolved in the solvent after cooling and filtration. Other factors include incomplete precipitation, loss during transfer steps, and impurities that prevent optimal crystal formation.

How can I improve percent recovery in recrystallization?

To improve percent recovery in recrystallization, use the minimum amount of hot solvent necessary to dissolve the compound initially. Cool the solution slowly and thoroughly, potentially using an ice bath. Scratching the flask or seeding with a pure crystal can also induce crystallization.

Does the choice of solvent affect my recrystallization recovery?

Absolutely. A solvent with ideal solubility properties is crucial. It should dissolve the compound well at high temperatures but poorly at low temperatures. Select a solvent that minimizes the solubility of your compound at cold temperatures to improve percent recovery in recrystallization.

What happens if I add too much solvent during recrystallization?

Adding too much solvent will result in a dilute solution. This means a significant portion of your desired compound will remain dissolved even after cooling, drastically lowering your percent recovery in recrystallization. Evaporating excess solvent can help, but may introduce impurities.